Tuesday, July 26, 2016

Thursday, July 7, 2016

A tree and a bush, and with leaves

Today I made an attempt to make a tree and a bush using Noch Leaves. Here is the result.

I think it came out quite good. But I did not arrive at this result at the first attempt. Here is the story, albeit in a somewhat condensed form.

I started out with the small wire tree I did some time back. It just had a few brown leaves, like this.

My first try to add leaves included wads of fiber as a foundation for the leaves to come. The fibers were also spray painted with gray, brown and black colors. At this point, everything looked promising.

On came the leaf material, and although the leaves themselves were OK, the overall impression was not that convincing. It looked as if someone had draped the trunk and the branches in a green coat. It was simply to dense, and did not have that airy look of a real tree.

In my head I had the pictures of the superb trees made by Jos Geurts, and as shown here as well as on other places on the net. So how does he do it?

Turns out he does not use wads of fiber, as I falsely remembered, but loose fibers. First sisal fibers and then static grass fibers. So I ripped the over-coat off the tree, and sat out to try doing it in the same way as Jos.

First I sprayed the bare tree with hair spray and sprinkled on some fibers, which barely shows in the first picture. This is followed by some 2 mm static grass fibers, and last Noch Mid Green leaves (07144).

Much better! Far from Jos' excellent trees, but I'm happy with the result. Looks more airy and lighter than the first tree.

While I was at it, I also made a bush from some wire strands. Here it is, first with the two applications of fibers, and then after adding Noch Olive Green leaves (07140).

And once again, planted on the layout.

I started out with the small wire tree I did some time back. It just had a few brown leaves, like this.

On came the leaf material, and although the leaves themselves were OK, the overall impression was not that convincing. It looked as if someone had draped the trunk and the branches in a green coat. It was simply to dense, and did not have that airy look of a real tree.

In my head I had the pictures of the superb trees made by Jos Geurts, and as shown here as well as on other places on the net. So how does he do it?

Turns out he does not use wads of fiber, as I falsely remembered, but loose fibers. First sisal fibers and then static grass fibers. So I ripped the over-coat off the tree, and sat out to try doing it in the same way as Jos.

First I sprayed the bare tree with hair spray and sprinkled on some fibers, which barely shows in the first picture. This is followed by some 2 mm static grass fibers, and last Noch Mid Green leaves (07144).

Much better! Far from Jos' excellent trees, but I'm happy with the result. Looks more airy and lighter than the first tree.

While I was at it, I also made a bush from some wire strands. Here it is, first with the two applications of fibers, and then after adding Noch Olive Green leaves (07140).

Sunday, May 15, 2016

A wire fence

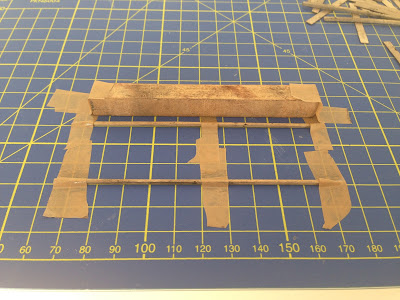

More fencing, this time a wire fence built from two sizes piano wire and some metal mesh. The first picture shows how I laid out the piano wire posts and top rails on a piece of wood, held in place with tape.

Next I soldered the posts and rails together. I also added a few brace posts.

After having cut a suitable piece of wire mesh, diagonally from a larger piece, I attached the mesh. That turned out to be easier said than done. The mesh was painstakingly "unruly" and had its own ideas on how to behave. And sitting tight was not one of them.

My initial idea was to glue (CA) the mesh to the supporting structure, but I gave that up and instead soldered it in place. The next two pictures show the fence after having been sprayed with a grey primer.

In the last picture the mesh shows traces of me wrestling with it. Those parts will hopefully be disguised by weeds and stuff. Some weathering and rusting is also to come.

Next I soldered the posts and rails together. I also added a few brace posts.

After having cut a suitable piece of wire mesh, diagonally from a larger piece, I attached the mesh. That turned out to be easier said than done. The mesh was painstakingly "unruly" and had its own ideas on how to behave. And sitting tight was not one of them.

My initial idea was to glue (CA) the mesh to the supporting structure, but I gave that up and instead soldered it in place. The next two pictures show the fence after having been sprayed with a grey primer.

In the last picture the mesh shows traces of me wrestling with it. Those parts will hopefully be disguised by weeds and stuff. Some weathering and rusting is also to come.

Sunday, April 24, 2016

Monday, April 18, 2016

A longer fence

I have built a longer fence, and put it down more permanently on the layout. This time I also made an attempt to at making nails. I tested various ways of doing this but ended up simply making a mark with a pencil. Here are some pictures.

The grass, which I though would be suitable for O, looks to thick I think.

The grass, which I though would be suitable for O, looks to thick I think.

Sunday, April 10, 2016

A wooden fence

Today I built myself a short wooden fence. As with the stone walls I did a while back I'm testing methods. The intention being that there will be stretches of fences and walls along the track, towards the backdrop.

Since the boards making up an O scale fence are quite wide,and at the same time very thin, I found it hard to find any scale lumber that would do. If it was wide enough it was way to thick. What I eventually did was to get some 0.4 mm (1/64 in) plywood, which I would to cut into 4 mm (5/32 in) wide boards.

So let's start. Here is the plywood where I have cut off 40 mm bit, corresponding to the height of the fence, which would be about 2 scale meters (about 6 ft).

Next I used my NWSL Chopper to cut the plywood into individual boards. First I did not see that the Chopper's stop had a tendency to not stay put, making some of the boards too wide. Easily avoided once I had realized that this happened, but it made slowed down the whole process.

Also, the razor blade was a little to short, so the Chopper would no cut the complete length of the boards. But that was easily fixed with an X-Acto knife.

Once all the boards for my test fence had been cut, I soaked them in an India ink wash, along with the scale lumber I was to use for posts and supports. Here are the boards, once dry out of the wash.

I then laid out a simple jig, along with the horizontal support boards, and began gluing boards to the supports.

Soon they were all in place, along with two vertical posts.

When the glue had tried it was time to pose the fence on the layout.

Not that bad I think. And there are no more excuses for not building longer stretches of both fencing and stone walls.

Since the boards making up an O scale fence are quite wide,and at the same time very thin, I found it hard to find any scale lumber that would do. If it was wide enough it was way to thick. What I eventually did was to get some 0.4 mm (1/64 in) plywood, which I would to cut into 4 mm (5/32 in) wide boards.

So let's start. Here is the plywood where I have cut off 40 mm bit, corresponding to the height of the fence, which would be about 2 scale meters (about 6 ft).

Sunday, April 3, 2016

All rail done

Finally I have managed to get all rail painted and weathered. Some new pics.

With that all done I hope to get started on some scenicking, or car or engine detailing...

Sunday, January 31, 2016

Stone wall, part 3

The stone wall I showed in the previous post have stones that looks merely stacked on top of each other. Although that can certainly be the case in the real world, at least in older times, I wanted to try a wall with mortar between the stones.

So I sat ought to do a short test section in the same way as before, but now with spackling compound between the stones. I went about more or less as you would apply mortar between real stones.

Once the compound had dried I proceeded as with the previous wall with an India Ink wash, some additional colouring and last some moss. Here is the finished wall.

And for comparison, alongside the one without mortar.

The second one is OK as well. It's just different. But I think I like the first one better. But of course, it all depends on what kind of wall you want to replicate and what fits the rest of the scenery.

So I sat ought to do a short test section in the same way as before, but now with spackling compound between the stones. I went about more or less as you would apply mortar between real stones.

Once the compound had dried I proceeded as with the previous wall with an India Ink wash, some additional colouring and last some moss. Here is the finished wall.

Saturday, January 23, 2016

Stone wall, part 2

I finished my stone wall test today.

I first gave it a somewhat uneven India Ink wash, followed by some dry brushing - gray, concrete and brown colors. After this I sprayed the wall with Testors Dullcote.

I wanted part of the wall to be overgrown with moss. For moss I used Woodland Scenics T49 Blended Turf - Green Blend. I applied white glue with a small brush where I wanted the moss, and then sprinkled on the turf. I then immediately shook and blew the excess turf away.

I'm really happy with the result.

I wanted part of the wall to be overgrown with moss. For moss I used Woodland Scenics T49 Blended Turf - Green Blend. I applied white glue with a small brush where I wanted the moss, and then sprinkled on the turf. I then immediately shook and blew the excess turf away.

I'm really happy with the result.

Sunday, January 10, 2016

Stone wall test

I wanted to model a stone wall, with moss and lichen. I could think of a number of ways of doing this, and buying a ready-made casting was not one of them. What I could do was to for instance:

- Do a simple plaster casting and scribe a stone pattern on to it

- Scribe or imprint a stone pattern in a piece of extruded foam

- Build the wall from individual stones

I've done the first two in other (N scale) projects so I settled for the last one. Might (perhaps) be doable in O scale, which as you know is the scale for my current layout.

First I got myself a bunch of O scale stones. I made them from a flake of not yet cured plaster which I first scribed and broke into strips. The strips where then cut up into more or less rectangular stones. Like this:

I then built a support structure from styrene...

...on which I then stacked the stones and secured them with ordinary white glue. I applied the glue in the back, towards the support only, since I did not want any glue on the visible parts of the stones. Any glue on the stones would ruin any later staining. Here four rows of stones are in place:

And finally we are done:

I admit, the resulting surface is a little on the uneven and rough side. A real stone layer, working with cut stones, and producing a result like this would most probably have got sacked! But for a first test I think it came out quite nice.

Here is a shot with the wall on the layout. The height of the wall is about 1.5 scale meters (a little less than 5 feet).

Next up is staining and painting, followed by the application of lichen and moss.

Saturday, January 2, 2016

A Contact Problem

I have made some layout work during the holidays

- I am done painting the back of all rail meaning I could swap the layout around, so that the front is once again forward faced as intended.

- I have replaced the wheels on the remaining two cars, so now all (3!) of them have wheels with proper /115 treads.

- Finally I changed the wheel axles on the engine, so that my re-gauging for standard O gauge would work better. The existing axles were shorter and for the more narrow, but prototypically correct, Proto:48 gauge.

With all this done it was time for some running, But before I could do that I had to clean the rail heads (before I mess them up again when doing the weathering on the front side). Said and done, and with both clean engine wheels and rails I set out on a back and forth run. A few dirty spots remained, but with those taken care of I still had problems near then end of the track. In the very same spot the loco stopped dead every time.

A light push and it started up again, but then went silent. After many more attempts to clean rails and wheels, to no avail, I finally brought out my voltage meter. I soon found out that at this very spot none of the wheels on the right side made electrical contact with the rail beneath it! How could that be?

If I lightly pressed on the right of the loco there was once again contact. I first thought the problem was that the roadbed was leaning in some way, making the right hand wheels suspended in the air. But that could hardly be the case. The trucks would surely be able to take up any small (invisible) misalignment like that.

Something else must make the wheels rise. So what could make them climb? When I thought "climb" I finally understood. It turned out the track gauge was on the narrow side in that spot, which made the wheels climb ever so little. It was barely not visible, but enough to make the wheel treads loose contact with the rail heads. The flanges still had contact with the sides of the rail head, but there my newly applied paint and weathering stopped any electricity from coming through.

I really ought to pull the rail spikes in that section and move one of the rails, but for now I just removed the paint from the uppermost part of the rail head - and no more spurious stops in that spot.

Subscribe to:

Posts (Atom)