I used hardboard for the fascia. Fortunately I had a few strips left over from when I did the fascia for the previous layout. I started by clamping the hardboard to the bench work. With a pencil I then traced the terrain contour on the back of the hardboard. I removed the hardboard strips and cut them along the pencil trace, and clamped them back again. This is a picture of the progress at that point.

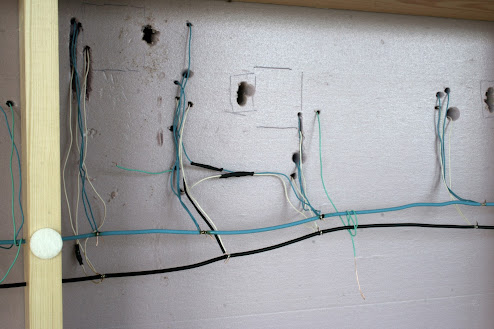

To make things more convenient while I worked along I flipped the whole layout over, letting it rest on its back. I marked the locations of the toggle switches, and then drilled pilot wholes right through both the fascia hardboard and the bench work.

With the fascia once again removed I then drilled larger holes in the bench work, using the pilot holes to find the proper location for each hole. The holes are large enough to contain the toggle switches.

Making these large holes turned out to me a rather messy affair.

While I was doing the fascia I took the opportunity to expand the layout at one end. The bench work for this layout has been taken from my previous layout, after having been cut down to make it less deep. But the backdrop at one end is still sized after the old layout depth. So now I made a small extension. Like this.